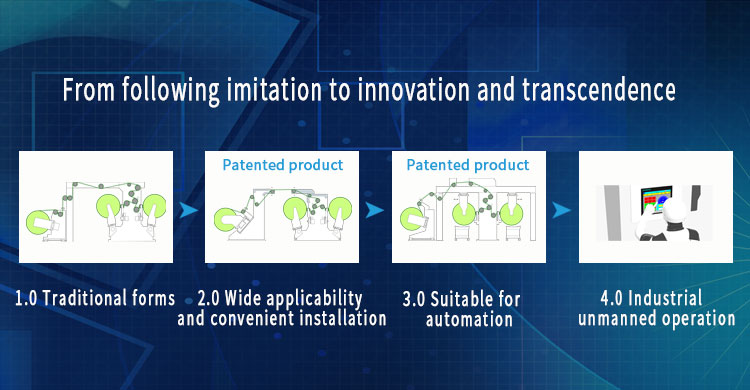

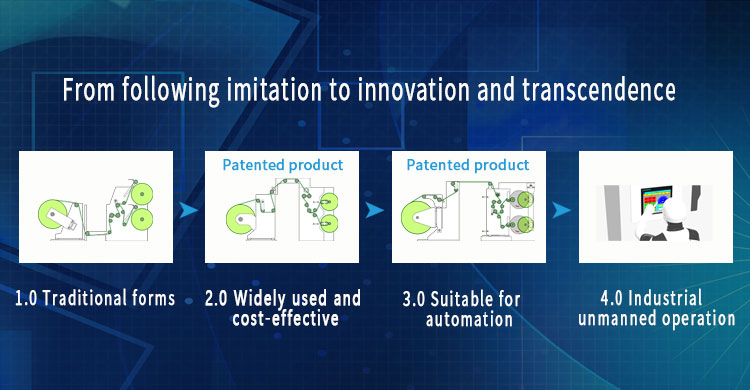

Slitter

1.0 Slitter

- Suitable for ordinary packaging, stable performance, convenient operation

- Suitable for ordinary packaging, stable performance, convenient operation

2.0 Slitter

- Flexible design of key parts to improve material adaptability and reduce wrinkles

- Dual structure, simpler installation and more flexible layout

- The frame structure is optimized to make the machine run more stable

- Intelligent, high degree of automation, improve accuracy and production efficiency

- Dual structure, simpler installation and more flexible layout

- The frame structure is optimized to make the machine run more stably

- The combination of contacting and following-up winding forms has stronger adaptability to materials

- The intelligent process fits the material characteristics, and the winding effect is better

3.0 Slitter

- The winding suspension makes the overall layout more optimized and can better adapt to the slitting of high-end materials

- The winding suspension translation not only makes good winding effect, but also is conducive to automatic packaging

- High degree of intelligence and automation improve the accuracy and production efficiency

- High end appearance, new visual experience

- The pressing roller moves backward with the main body of the frame, which is especially suitable for high-end materials with low tension and low surface friction coefficient

- Four axis turnover with automatic coil unloading, coil changing without shutdown, which is suitable for automatic docking

- High degree of intelligence and automation improve the accuracy and production efficiency

- High end appearance, new visual experience,which is suitable for high quality materials

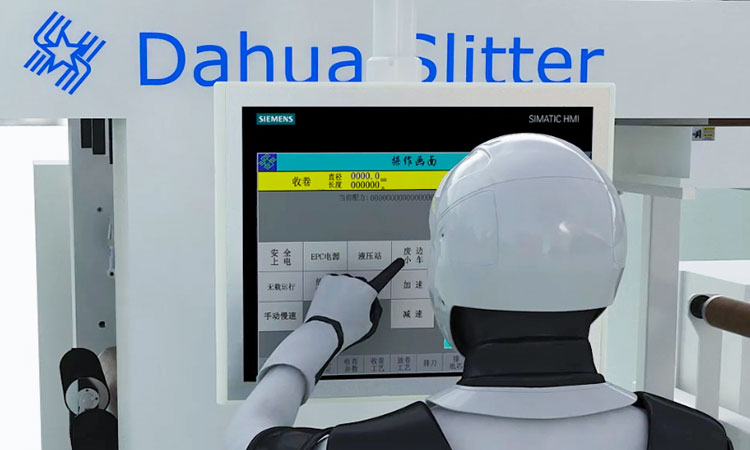

4.0 Slitter

Unmanned production under industry 4.0 is currently under development. Please look forward to it!

Ultra Wide Primary Slitter

10.4 meters film width ultra wide slitter is under development. Please look forward to it!

English

English Spain

Spain